Menu

Why Are Louis Vuitton Bag Prices So Expensive?

May 23, 2016 2 min read

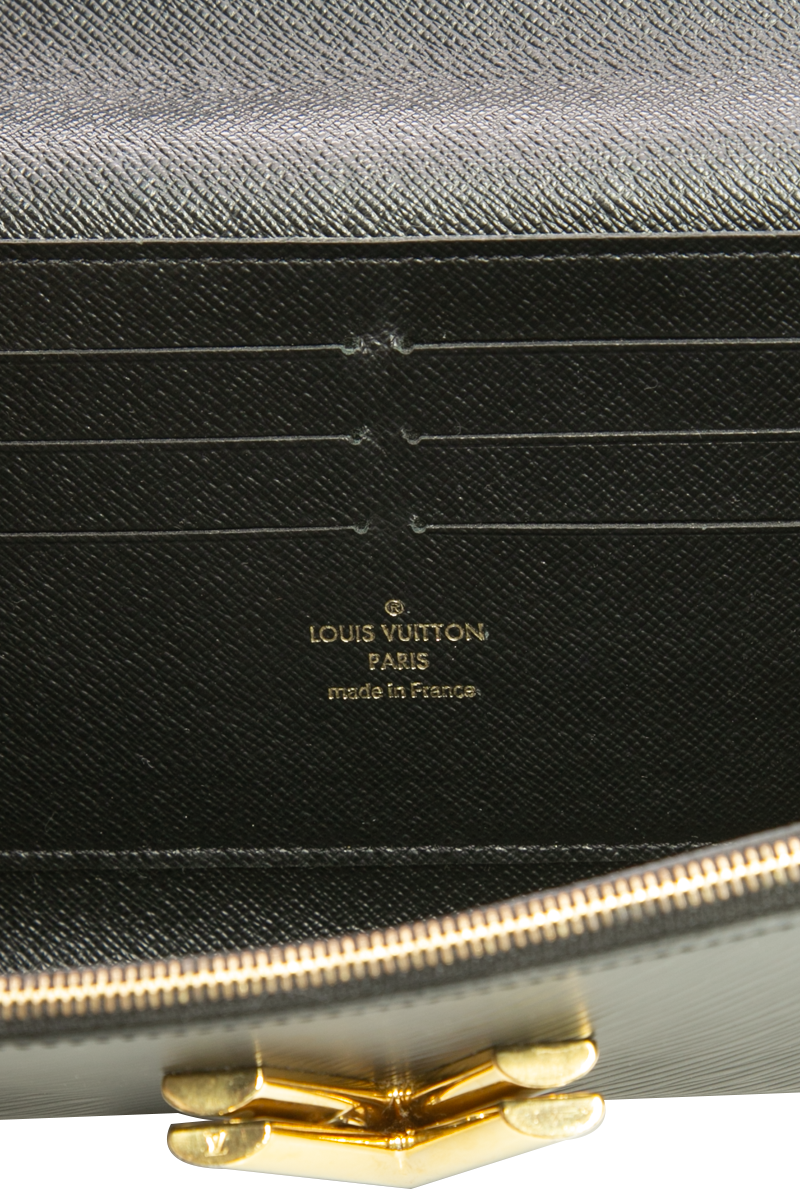

#1: Where Louis Vuitton Bags are Made

All Vuitton workshops are located in Europe or the United States, and craftspeople are paid fairly for their skill sets... in other words, there are no sweatshops involved in production. Vuitton craftspeople complete over a year of training before working independently. Some special LV pieces require over 300 steps to produce, but the average is about 100 steps. Vuitton bags are made to last a lifetime, and the company operates repair centers all over the world. For a small fee, any worn part of the bag can be replaced for the entire life of the bag.

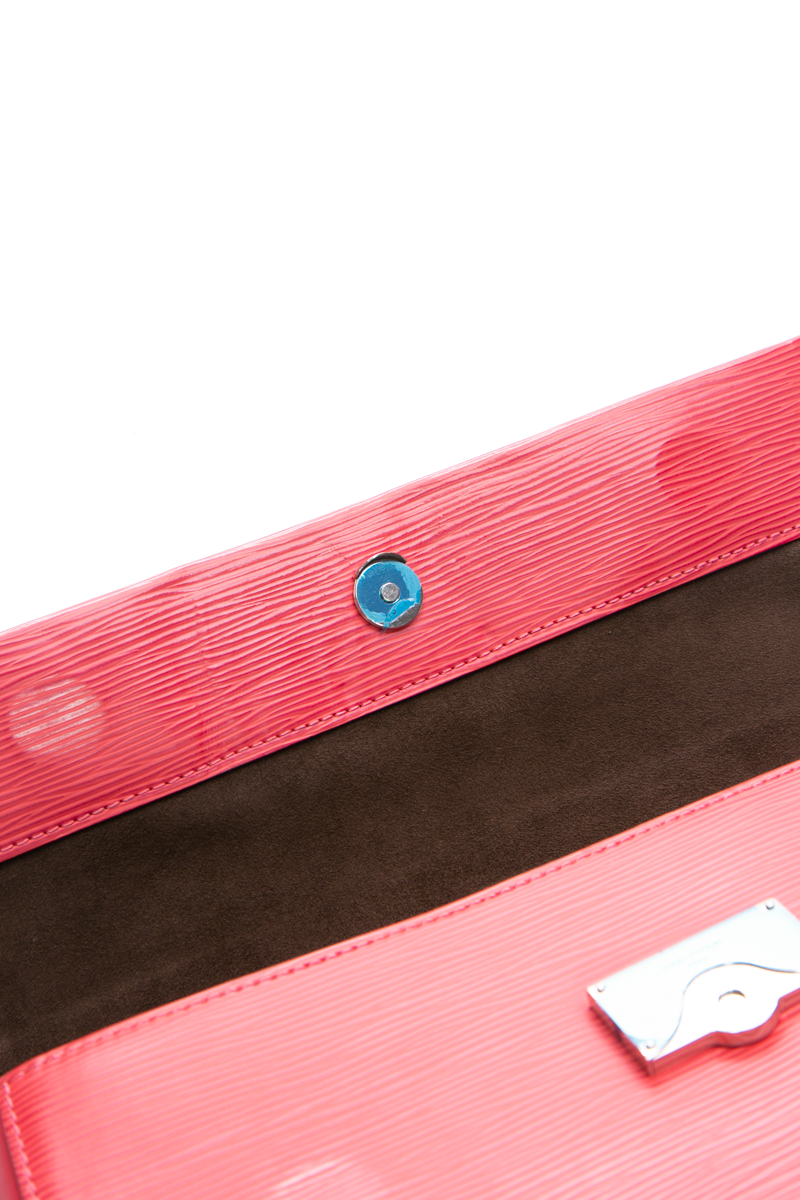

#2: The Standards LV Uses When Selecting Materials and Crafting Bags

All skins, including Vachetta leather, are inspected for blemishes and imperfections before production begins. Many of Vuitton's exotic skins such as croc and python are burnished to a shine by hand using rolling agate stones. Vuitton's coated canvas products are made to be water repellent and stand up to extreme wear. In the final stages of production, top-stitching and edge-glazing are done by hand.

#3: The Quality Control Process Vuitton Uses to Test New Bag Models

Louis Vuitton has an insane quality control process, employing a bevy of custom-made robotic machines that simulate extreme wear and tear. Zippers and closures are opened and closed more than 5,000 times, materials are exposed to UV light rays, and bags are dropped repeatedly for days on end with 7 pound weights inside. It may sound extreme, but these torture devices yield some of the most durable luxury goods on the market.

Let us know: do you own an older Louis Vuitton bag? If so, which one and how long have you had it?

Recent Articles

- Louis Vuitton Essentials: Start or Grow Your LV Bag Collection November 08, 2024

- Personality Meets Style: Choose the Luxury Piece That Defines You October 16, 2024

- Van Cleef & Arpels: A Legacy revived October 01, 2024

- What is Paris Fashion Week? September 24, 2024

- Perfect bags for going back to Campus September 06, 2024

Let customers speak for us

from 2291 reviews

Quality bags and wonderful staff!

Had the best experience buying my new sunglasses! Loved the selection and being able to try everything on in the store.

Thoroughly happy with my purchase. Amber was lovely. So many bags to choose from. I love my Prada bag. Like new condition means it looks brand new. Perfect condition.

I’ve had an LV bag on my bucket list for a very long time. I noticed CoutureUSA on Facebook recently and decided to visit their Tampa location as I could never buy an LV online without seeing it in person first. I was a bit skeptical having never been in a consignment store before; however, I was very impressed with the high end products offered, condition and pricing. I purchased a beautiful LV bucket 🩷with the assistance of Amber who was just fabulous. I highly recommend this Tampa boutique and purchasing an authentic designer item. I will be back in the future and always checking out their website for new arrivals!

The staff were so lovely and

I recently purchased a YSL bag from Couture USA and am thrilled with my experience! The bag is in pristine condition, authentically verified, and a fantastic value for a high-end piece. The selection of luxury bags is impressive, with curated styles from top designers. Customer service was friendly as always and efficient, making the process smooth. Highly recommend for anyone seeking pre-loved designer gems!

Thanks Amber!

This is my second order and again they did not disappoint! I absolutely love my purchase and it looked better in person which delighted me even more.

I love here. Bags are in great condition.

I LOVE this store! It has the biggest selection and best quality I have come across. The staff are so nice and accommodating.

I would highly recommend you buy from here.

I always have a positive experience with Amber and Alina. Whether it’s in store or purchasing online, it’s always fun and positive. The products are beautiful and authentic. I always feel special. After so many years, it’s like visiting friends when I walk into store.

Very nice luxury boutique. Girls working there are so friendly. Amber was very patient & helpful. You can find like new bags way under retail. Fun place to shop!

This was my first time visiting this designer consignment shop, and wow—next level! The selection is incredible: Chanel, Louis Vuitton, Dior… row after row of stunning bags at amazing prices. The staff couldn’t have been nicer, and the owner even came out to introduce herself—she’s an absolute wealth of knowledge.

I wasn’t even in the market for jewelry, but I ended up falling in love with (and taking home!) a white ceramic and rose gold Bulgari ring at a fantastic deal. I’m officially hooked and will definitely be back!

It’s always a fun experience to stop by and chat and see what’s new. This time I came away with the cutest LV phone bag. I’ve been wearing it ever since.

LV bag exactly as described in Excellent condition. I asked for a few more pictures of the purse and they were promptly posted. Item arrived on time as expected and I could track my package from start to finish to ensure I was home to sign for it. I LOVE my bag and will be purchasing from Couture USA again!

Great Price for a great bag! Exactly what the pictures showed!

Couture VIP

Sign up now for exclusive pre-sale alert before anyone else!

+30 OFF your first purchase of $300 or more